Environmental engineering equipment

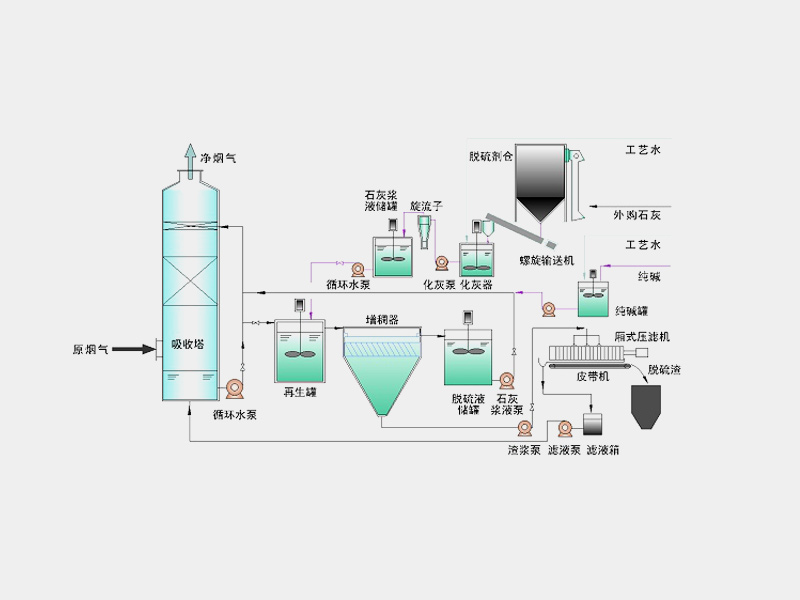

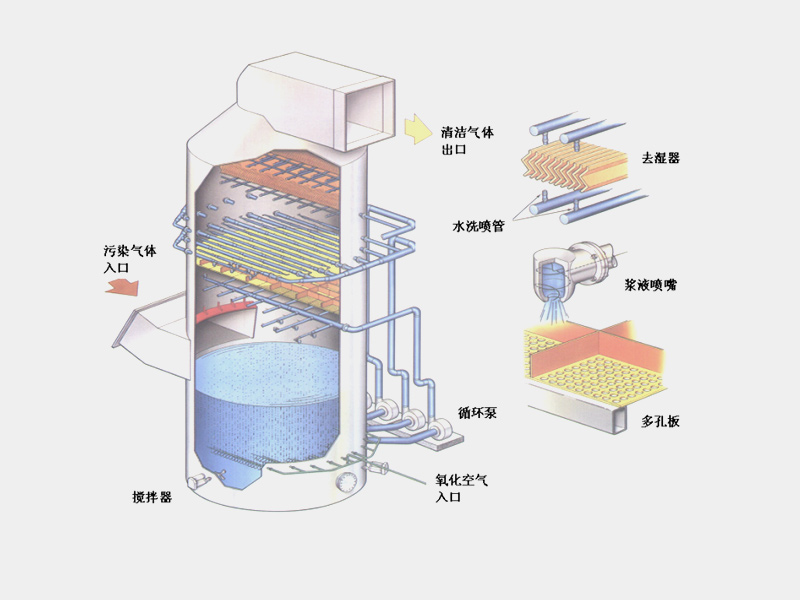

The gas enters the wet absorption tower of the desulfurization device, and is in countercurrent contact with the alkaline limestone slurry spray droplets sprayed from top to bottom. The acidic oxide SO2 and other pollutants such as HCL and HF are absorbed, and the flue gas is fully purified; The slurry after SO2 reacts to generate CaSO3, which is forced to oxidize and crystallize to generate CaSO4•2H2O. After dehydration, a commercial-grade desulfurization by-product—gypsum is obtained, and finally the comprehensive treatment of sulfur-containing flue gas is realized.